Artificial intelligence is nowadays used by more and more organizations representing various industries. It is leveraged by companies in e-commerce, banking, healthcare, commercial and many others. AI has proven itself to be very useful for manufacturing companies as well. It may be applied in different company departments to improve their work efficiency. Learn how it can be applied in your company to improve efficiency.

Artificial Intelligence in manufacturing can be used in many ways. It is important to mention that it can be used in many departments for various purposes, so once you learn it’s potential for manufacturing-related tasks and decide to implement the technology, you should also consider enhancing your other business software and tools with AI. We explain how a certain way of using AI could enhance your company productivity.

Do manufacturing company really use AI?

Artificial Intelligence is a really wide branch of computer science, and its main goal is to build more smart machines and applications that would be capable of performing tasks which require human-like intelligence. There are multiple subfields of AI used in order to improve companies day-to-day operation – such as neural networks, machine learning and deep learning. Some people hear “artificial intelligence” and imagine pictures straight from a science fiction movie – robots taking over the earth. We are not there yet – technology is not so advanced for now, but it may already be very useful in the manufacturing sector and many others.

According to PWC Digital Factories 2020. Shaping the future of manufacturing report, 91% of industrial companies invest in creating digital factories in Europe. More than a half of surveyed organizations use predictive data analytics and machine learning to make better operational decisions. It is expected that 20% of the companies will use artificial intelligence in the next five years (in 2020 only 9% of companies used it). It is understandable – AI is getting popular very fast and allows reducing costs and increase profits of each company that uses it wisely.

How can AI-based solutions improve your day-to-day operation?

Manufacturers encounter various challenges that need to be handled efficiently (like machinery failure, high costs of production etc.). AI and other related technologies (such as machine learning) can significantly improve operational efficiency of your manufacturing company. Scaling AI in Manufacturing Operations: A Practitioners’ Perspective report created by Capgemini Research Institute indicates that AI is used in the manufacturing industry mainly for maintenance (29% of use cases) and quality monitoring (27% of use cases). There are many benefits of implementing AI-based solutions in manufacturing.

Improved safety in work environment

Industrial workers often deal with heavy and dangerous machinery. It is crucial to ensure their safety. Workplace monitoring is one of the most common uses of artificial intelligence in business. Machines that leverage artificial intelligence may apply visual vision and video analytics to generate real-time alerts when some object is identified and found in a pre-defined area, and shut down the machine that could cause injuries. In the times of pandemic, this technology may also be used for thermal screening of employees and assessing if they could be sick. Artificial Intelligence could improve safety of the employees in many ways.

Production optimization

Artificial Intelligence can help companies make their products better. Digital twins is a method that could be applied before the physical product is actually manufactured. A digital model of an original product is created and a special application collects data from the virtual model to improve the original product. This technology also enables efficient product personalization. A manufacturer can create many types of one product.

Enhanced cybersecurity

New technological opportunities come with greater risk – fortunately, artificial intelligence gives you the ability to protect your connected IoT devices, heavy machinery, monitoring cameras, business applications and software. AI can help you tackle the most important cybersecurity challenges. With the right AI-based tools, you can take advantage of producing massive amounts of security logs and data, by analysing them and searching for abnormalities. Artificial Intelligence can easily go through your data in real-time, looking for signs of intrusion and informing you (or even taking first actions) when detecting malware, fraud or suspicious employee behaviours.

Cost reduction

There are many ways to cut expenses and increase profits using AI. First of all, by improving cybersecurity, you reduce the possibility of losing valuable resources and protecting your organisation from paying the fines in case of a breach. Predictive maintenance allows you to predict potential accidents and machinery errors by analysing sensor data. This way, a manufacturer knows when and if the organisations’ equipment could fail, and they have it repaired or replaced before the failure actually occurs. Through such measures business is prevented from expensive downtime. AI-based solutions for business may also handle optimizing the energy and other resources’ usage for example by choosing an optimal temperature or changing the light intensity in the room.

Faster decision making

Artificial Intelligence-based solutions can be applied in all business departments. Manufacturers collect large amounts of data and may perform both batch data analysis and real-time analysis to support numerous processes in your company. Having access to such powerful analytics of various data improves an organisation’s day-to-day operation. You can make your business decisions, change approaches to managing the business and deal with many challenges earlier than others, which grants you operational and competitive advantage.

Application of AI in manufacturing

Artificial Intelligence-based solutions for manufacturing allow you to produce better products in a more efficient way, by optimizing the use of numerous resources and automating various processes. Learn some interesting applications of AI in manufacturing.

Detecting defects with deep learning

Originally, detection of defects in the products was handled by quality specialists. It is a very important process, as in some products (for example electronic devices) small defects can affect the whole system and make a thing the product useless for the customer. Today, the process of detecting defects along the production line is getting smarter. Deep neural networks are capable of recognizing defects on the surface of the products – such defects as leaks, cracks, scratches etc. There are multiple techniques that make this possible, such as image classification or object detection. Special applications can send your technical employees notifications when some problems are found, so they could react.

Preventing machinery failure

Artificial Intelligence-related technology may include data modelling. This powerful analytics solution can predict a machinery failure, so you may undertake preventive measures, instead of fixing the problem when it actually occurs. Machine-learning algorithms can analyse failure patterns to foresee technical problems using data gathered by sensors – moisture, temperature, density etc. There are several machine learning models that can be leveraged to handle that task:

- regression models,

- classification models,

- anomaly detection models.

ML-based methods ensure high accuracy by revealing potential issues early and allowing you to maintain your industrial machinery properly and optimize its performance when possible.

Forecasting based on data from IoT devices – energy consumption

Multiple processes can be automated with access to relevant data, but automation is not the only thing that can improve the way your organisation works. With Internet of Things devices getting more popular in business, you may gain access to many productive sources of data that can be put to a good use thanks to machine learning and deep learning. Collecting and processing historical data can give you a lot of interesting information about your business resources use and energy consumption. With advanced technology, you can forecast future consumption and use this information for example to plan expenses and reduce overall costs of running your company.

Digital twins

As already mentioned, digital twin is a virtual copy of an actual production system. You can leverage a digital twin of a certain machinery system component or of a whole machinery system. The main goal of this process is to create a better, improved product. Such procedure is performed in order to run real-time diagnostic and evaluation of the production process.

And how do digital twins work? Digital twin models need to be taught how to optimize a physical system or product. Models are used to process the data and look for the behaviour patterns and anomalies. Then, ML algorithms help to optimize production scheduling, handle quality improvements and the whole production process maintenance. Additionally, you may use natural language processing techniques to involve data from external sources (industry reports, social network, expert articles).

Raw materials’ price forecasting and supply chain management automation

Prices of materials depend on a variety of factors and can change dynamically when demand is growing. Supply chain management may also be automated and optimized using Artificial Intelligence and machine learning algorithms. Advanced supply chain management systems equipped with AI-based solutions are able to automatically monitor data such as material inventory, market trends, consumer preferences, weather forecast and traffic. All this information may prove used for optimization and automation processes in your company. For example, with advanced analytics, you can predict raw materials prices in the future. You can also use ML algorithms to shorten transportation time by reviewing all possible routes and defining the fastest ones.

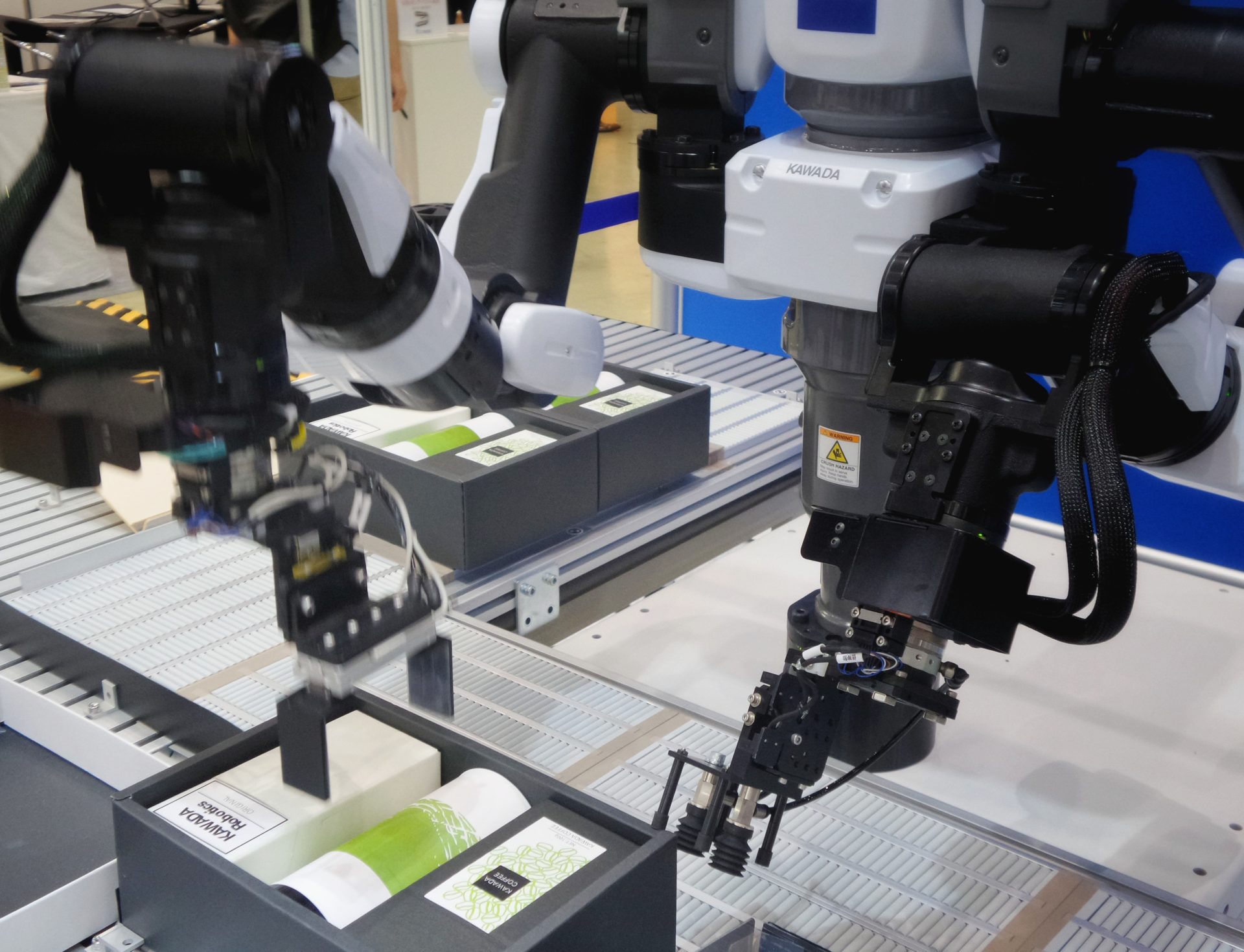

Manual tasks automation

Artificial Intelligence may also be used to automate multiple tasks. Robotic process automation (RPA) can be used to deal with numerous repetitive jobs in the factory. It reduces and prevents so-called human error in the production process and saves your employees time, so they could focus on work that actually requires human touch. Robots can do a lot of things – paint, weld, pick and move things from one place to another, drill or even check the quality of components. Robots may be equipped with machine vision, which enables them to work safely alongside human employees on tasks that cannot be fully automated.

Importance of data preparation for AI

Artificial Intelligence and technologies such as machine learning are all about data. Nowadays, information is a very important business resource. Gathering data is not enough, however. You need to ensure high quality and appropriate type to receive accurate analytics results and leverage the power of AI.

The more data sources you have, the more accurate your predictions will be. But you do not only need to store data, but also make sure that it is actually useful. You may improve data quality by performing several processes such as data cleaning – eliminating information that is incomplete, irrelevant or not reliable from the point of view of analysis. To reduce the possibility of collecting poor quality information, you should also pay attention to the data source and leverage techniques that prevent clients from putting incorrect information in the forms.

To sum up

Turn your company into a modern organisation using Artificial Intelligence and related technologies. Implementing AI-based solutions for manufacturing is not a small expense, but thanks to overall optimization of your business, you will be able to reduce costs of running your company and increase profits significantly. You may also make your employees’ job easier. Apart from such areas as production, quality assessment, workspace monitoring etc., you may also use software powered by AI in other departments of your company – finances, marketing, management, HR and many more to benefit from analytics and automation.

If you are interested in AI-based solutions that we can implement in your company to help you become more competitive in your industry, do not hesitate to contact our consultants. We will be happy to tell you more about solutions we can build for your business.

Andrzej Kopera • Sep 05

Andrzej Kopera • Sep 05